Australian Foam Laminators Group specialises in custom fabric solutions from Flame Lamination to CNC Cutting

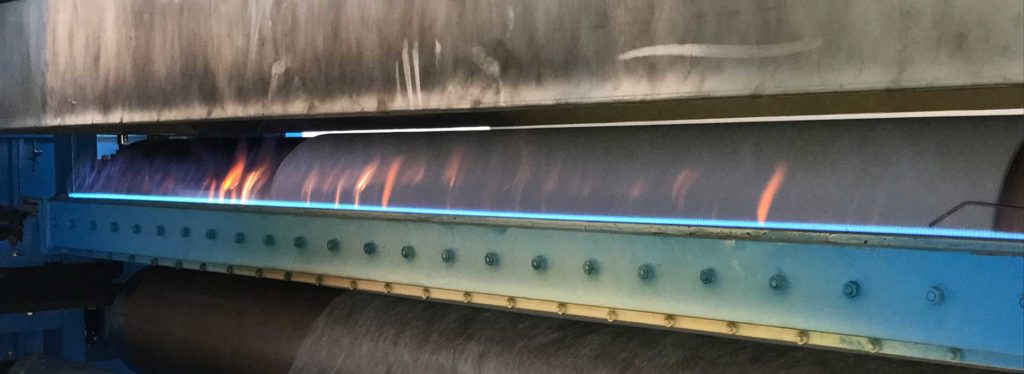

Australian Foam Laminators Group is the leading provider of Flame Lamination services in Australia, delivering high-performance bonding for flexible foam, textiles, and composite materials.

Our flame lamination process ensures superior adhesion, dimensional stability, and VOC-compliant bonding for critical applications in automotive interiors, furniture manufacturing and industrial components.

Alongside flame lamination, our services include adhesive lamination, textile treatments, slitting and rewinding, precision CNC cutting, as well as advanced 2D and 3D scanning.

With advanced lamination technology and strict compliance to OEM specifications and ISO standards, we provide end-to-end solutions for high-volume, quality-driven production environments.

Flame lamination is one of the most efficient and cost-effective methods of laminating materials with foam.

Industry Experts

AFL group delivers complete material-processing solutions, including flame lamination, glue bonding, fabric treatments, CNC cutting, and pattern digitising. From automotive seating to commercial upholstery, we create high-performance composites built to last.

Customer Focused

No delays, no excuses, no being left high and drySince 1964, B&R Converters has been trusted for specialist converting solutions, and today we proudly operate as part of the AFL Group. United, we deliver cutting-edge flame lamination, adhesive bonding, slitting, and textile processing that set the benchmark across Australia. With state-of-the-art facilities in Sydney, Melbourne, and our newest hub on the Gold Coast, we craft high‑performance laminated textiles for clients nationwide and around the globe.

Tailored Solutions

Every project is approached with your unique requirements in mind, ensuring results that fit your business perfectly.Reliable Quality

With decades of expertise and strict compliance to industry standards, you can trust consistent, high‑performance outcomes.Nationwide Support

With three fully equipped facilities backing each other up, we don’t grind to a halt when a machine does. Even if one site has an unexpected breakdown, your production keeps movingSustainable Practices:

Environmentally certified materials and eco‑friendly processes give you peace of mind while supporting greener choices.

Making AFL Group your lamination supplier of choice is a big winner for the environment – as well as a good business decision for your company